Services

Hastings Painting provides the following but not limited services to bridges, water towers, water treatment plants & tanks, structural steel, factories, plant shutdown and roof coating.

Lead Abatement (Levels 1, 2 & 3)

Renovating or remodeling an older structure can expose people to dangerous levels of lead. Sanding or scraping lead-based paint will create lead-containing dust. Even without any renovation activity and in the absence of any visible peeling or flaking, lead paint deteriorates over time and can release sufficient levels of lead to pose a health risk to people of all ages. Only professionals with specialized training in lead abatement and experience with specialized filtration equipment should attempt to remove lead-containing paints and coatings.

Hastings Painting has qualified and experienced personnel with lead abatement certification in levels 1, 2 and 3. Hastings Painting also utilizes high-powered HEPA air filtration systems (10,000 – 40,000 CFM) in lead abatement projects.

Sandblasting

Surface preparation is the most important procedure to the success of any coating application. Without proper preparation even the best coating applications can fail. Sandblasting is often a required and efficient method to prepare surfaces in order to achieve effective adhesion of coatings. By propelling abrasive media at high velocities, sandblasting effectively cleans and removes existing coatings, rust, scale and other contaminants.

Ultra High Pressure Water Blasting

High pressure and ultra high pressure water blasting is another form of surface preparation and cleaning. This procedure is sometimes used to effectively remove existing coatings and graffiti without the need for chemicals or the use of harsher methods.

Depending on the situation, Hastings Painting utilizes the appropriate equipment to deliver high pressure water blasting up to 7,000 psi for regular applications or 10,000-20,000 psi for ultra high pressure applications.

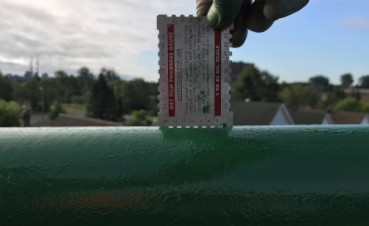

Protective Coatings

Protective coatings are important for extending the longevity of a surface especially where exposed to weather, water and other elements. They also serve to enhance appearance. The variety of different brands and types of protective coatings is quite extensive and selecting the correct product for an application can be complex. Hastings Painting has experience with a vast array of protective coatings and has the expertise to provide the correct solution for many applications and industries.

Floor Coatings

While floor coatings serve to provide an improved appearance to flooring systems they also provide protection leading to a longer lasting floor which is more resistant to staining, rusting, water deterioration and other forms of containment and damage. Floor coatings can also create a safer environment within a building or structure by adding non-slip media to the surface and highlighting areas of danger with reflective coatings.